The Definitive Guide to Logistics Companies Process

Wiki Article

Unknown Facts About Logistics Companies

Table of ContentsThe Only Guide for Stockyard Equipments7 Simple Techniques For Logistics Companies TransportationLittle Known Facts About Freight Logistics Companies.The Main Principles Of Stockyard Equipments About Stockyard EquipmentsSome Known Incorrect Statements About Freight Logistics Companies

The chemical as well as/ or physical features of some of the incoming resources can differ extensively and these materials need homogenization to have consistent attributes for meeting the need of the procedures where these materials are to be made use of. This homogenization operation is to be accomplished during the stacking and reclaiming of the products.The mixing procedure, when related to just one product to make it uniform in qualities, is labelled as homogenizing procedure. Considering that the mixing procedure i. e. blending of more kind of materials or homogenization of even more quality of solitary material is functionally very same, just word mixing is typically utilized for both the mixing as well as homogenizing procedures.

At least 2 accumulations are needed in the storage space lawn, so that when one accumulation is under development, the various other developed accumulation is utilized for redeeming of the product. If no mixing is required, then the cone covering technique is typically picked. It needs no slewing system/ gear in the stacker and also streamlines the motion of the stacker throughout stacking. logistics companies types.

The Logistics Companies Transportation Statements

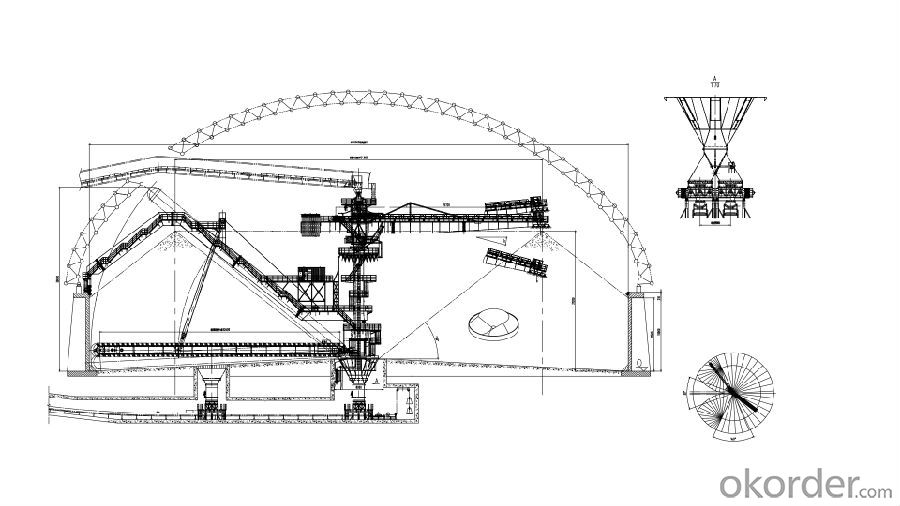

Chevron approach is the recommended option because it does not need slewing mechanism in the stacker. There are 3 primary sorts of storage space yard machines which are used for piling as well as recovering of materials. These are (i) stacker, (ii) reclaimer, and also (iii) stacker cum reclaimer. These yard devices are described listed below.The stacker is utilized for preparing the accumulation with the incoming material. The machine travels on rails with the product fed to it with the yard conveyor between the rails - logistics companies transportation. It is offered with a boom with a belt conveyor which is gone up and also down with the help of wire ropes or a hydraulic system.

The product coming on the lawn conveyor is elevated by a tripper affixed to the stacker and discharged right into the boom conveyor which carries the product as much as its end and also enables it to be up to form a stockpile. The stacker takes a trip continuously from side to side to make sure that the pile is accumulated layer by layer.

10 Simple Techniques For Transport And Logistics Companies

The tripper automobile is mounted in a structure put on hold from the structure roofing system. The traveling of the tripper car is PLC regulated and also configured to develop either a cone covering or a chevron stockpile. The type of stacker is selected based upon the accumulation layout, the material residential properties, as well as the required piling method.

The construction of a regular stacker with luffing mechanism as well as various kinds of stackers are shown in Fig 2. The tripper and major body are installed on bogies to move the stacker on the rail track along the storage space backyard.

Fascination About Freight Logistics Companies

The luffing stacker can make stockpile in chevron and also cone covering sort of formation. The luffing and also slewing stacker is used to make stockpiles on both sides of the maker. Along with chevron and also cone covering kind of developments (as official site a result of luffing capability), it can make accumulation in windrow and also strata kind of developments additionally (due to the slewing ability).The chute has two legs, one for guiding the product in the direction of the boom conveyor throughout piling and the various other for releasing the product in to the central chute over the influence table for bypassing the boom conveyor for straight loading to the backyard conveyor. A diverter gateway, run by an electric actuator or hydraulic cylinder closes any one of the legs and also permits the product to travel through the other, as needed.

The two kinds of reclaimers which are in common usage are (i) scrape reclaimers, and (ii) pail reclaimers. The traveling of chains along with scrape blades scratches/ drags the material from the accumulation and also releases it on the yard conveyor.

The Buzz on Logistics Companies Types

The scooped material drops on the receiving/ intermediate conveyor which can be bridge conveyor, boom conveyor, or barrel conveyor. The getting conveyor in turn releases useful link the material on the backyard conveyor. If there is a need for mixing then the material is scraped/ scooped from the face/ front (whole sample of the pile) of a heap.When material is scuffed/ scooped from the face of a stack, there is usually a harrow/ rake connected to the reclaimer which brings the material to the base, where it is occupied by scrapers or pails. The scraper type reclaimers are lighter in weight and also are less expensive as contrasted to flourish kind bucket wheel reclaimers.

Some Known Details About Shipping

Report this wiki page